THE TRINITY BLADES Combo

Introducing THE TRINITY BLADES by Site Inspections - The Essential Tools for Hard-to-Reach Locations in the Building Industry

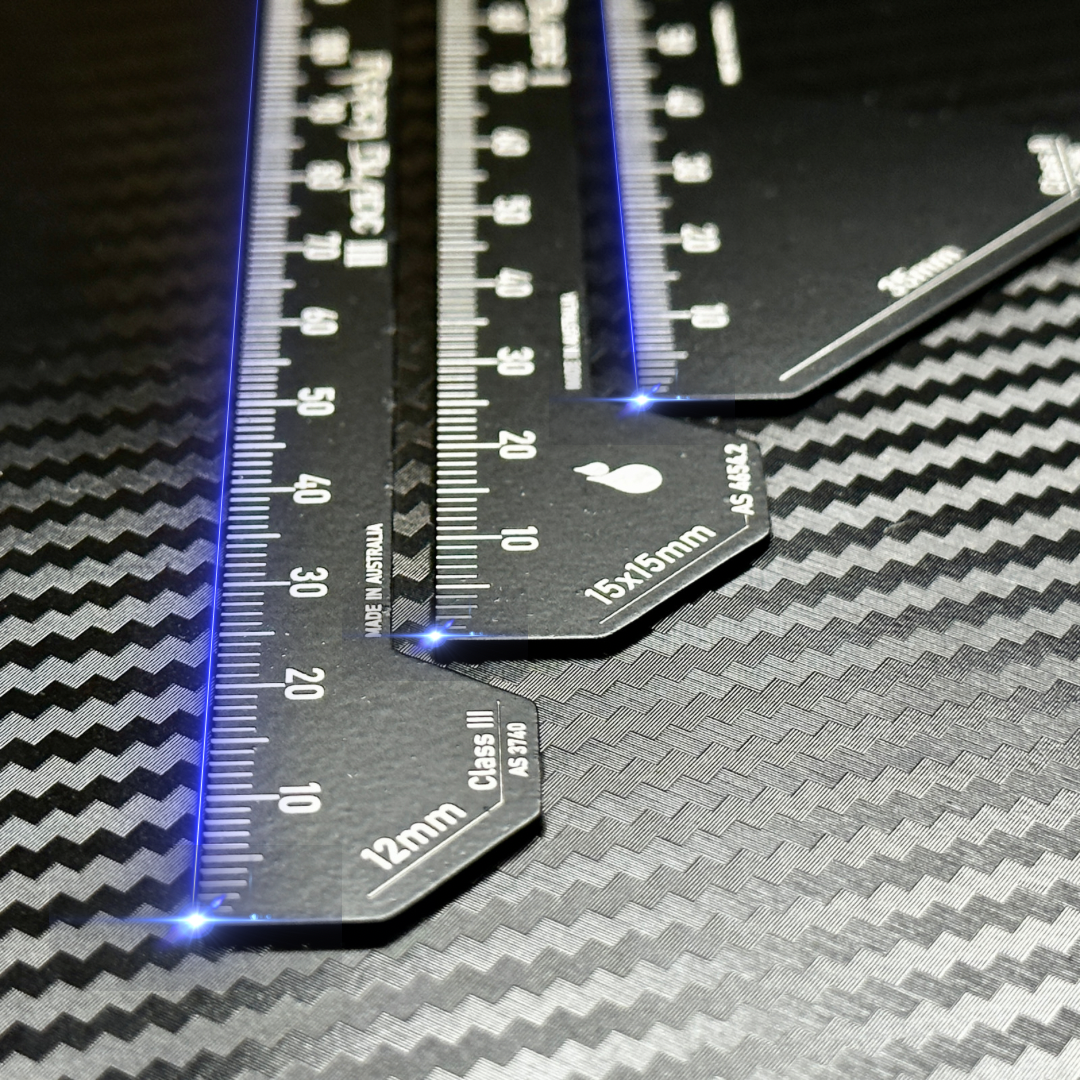

Site Inspections continues revolutionising the building industry with its latest offering - THE TRINITY BLADES. Comprising three distinct gauges, these tools are meticulously designed to measure fillet/bond breaker requirements in the most challenging, hard-to-reach locations.

The three blades in THE TRINITY BLADES set are as follows:

-

Blade I: Designed to provide a 15mm x 15mm minimum fillet/bond breaker measurement, as required by AS 4654.2, for external liquid membrane applications.

-

Blade II: Engineered to deliver a 35mm minimum fillet/bond breaker measurement, as per the AS 3740 requirements for class II liquid membrane applications.

-

Blade III: Optimised for a 12mm minimum fillet/bond breaker measurement, conforming to AS 3740 standards for class III liquid membrane applications.

It is crucial to consult the product manufacturer's Technical Data Sheet to confirm that the fillet/bond breaker sizes are compatible with the membrane system and comply with the minimum requirements stipulated by the Australian standards.

Each tool in THE TRINITY BLADES series integrates a 150mm ruler, facilitating easy measurement of the vertical membrane termination height from the structural floor or 25mm above the finished floor level, as required by AS 3740 + more!

The innovative design and tactical size of these gauges provide unrivalled access to challenging areas - be it under sliding doors leading to balconies or hard-to-reach corners. Being the only tools of their kind on the market, THE TRINITY BLADES are an indispensable addition to your professional toolkit.

Each gauge is manufactured from hardened 420 Stainless Steel and measures 1.2mm in thickness, ensuring durability and longevity.

THE TRINITY BLADES are more than just tools; they are an essential companion for various professionals, including:

- Waterproofing Applicators

- Builders

- Site Managers

- Building Consultants & Inspectors

- Third Party Compliance Testers

- Membrane Manufacturer Representatives

These professionals can attest to the significance of precision and efficiency in their roles. Always remember to verify the fillet/bond breaker dimensions with the product manufacturer's Technical Data Sheet to ensure alignment with the membrane system and compliance with the Australian standards.

Choose THE TRINITY BLADES - where precision meets accessibility and efficiency.

AS 3740 Table 4.10 Bond Breakers

Membrane class |

Elongation at break |

Minimum bond breaker/tape width |

I |

10 % to 59 % |

100 mm |

II |

60 % to 299 % |

35 mm |

III |

≥ 300 % |

12 mm |

NOTE 1 Bond breakers for Class I membranes (low extensibility) allow the membrane to flex rather than stretch.

NOTE 2 Bond breakers for Class II membranes (medium extensibility) allow the membrane to stretch. If a tape is used as a bond breaker, either the membrane will not bond to the tape or the tape will have elastic properties similar to the membrane.

NOTE 3 Bond breakers for Class III membranes (high extensibility) allow the membrane to have even thickness.

It's always essential to consult the product manufacturer's Technical Data Sheet to ensure that the fillet/bond breaker sizes align with the specific membrane system and satisfy the minimum requirements set by the Australian standards.

Exceptional Features

In addition to its primary function, the Reach Blade II comes with an integrated 150mm ruler, providing a simple solution for measuring vertical membrane termination heights from the structural floor or 25mm above the finished floor level and much more, as specified by AS 3740.

Its innovative design and compact size give Reach Blade II unparalleled access to challenging areas - whether under sliding doors leading to balconies or those hard-to-reach corners. As a unique tool in its category, Reach Blade II from THE TRINITY BLADES is a crucial addition to your professional toolkit.

Built to Last

Reach Blade II is crafted from hardened 420 Stainless Steel and measures 1.2mm in thickness, ensuring both durability and longevity even in demanding environments.

Who Can Benefit From Reach Blade II?

Reach Blade II is not just a tool; it's an essential companion for various industry professionals, such as:

- Waterproofing Applicators

- Builders

- Site Managers

- Building Consultants & Inspectors

- Third-Party Compliance Testers

- Membrane Manufacturer Representatives

For these professionals, precision and efficiency are paramount. With Blade II from THE TRINITY BLADES, they can elevate their work to new heights of accuracy and productivity.

Choose Reach Blade II from THE TRINITY BLADES, where precision meets accessibility and efficiency in the world of building inspections.

Examination of AS 3740 and AS 4654.2 Fillet/Bond Breaker Requirements:

AS 3740 Fillet/Bond Breaker Requirements:

- Definition: Bond breaker is a system that prevents the membrane from bonding to the substrate.

- Class II Membranes: These medium extensibility membranes require a minimum bond breaker/tape width of 35mm.

- Class III Membranes: These high extensibility membranes require a minimum bond breaker/tape width of 12mm.

- Bond Breaker Profile: Although not explicitly defined, the diagrams in the standard depict a concave finish for the bond breaker.

Two application options for class III membrane bond breaker:

- Option 1 (Mitre Finish): Sealant bead should extend up the wall and along the floor for a minimum of 8.49mm each (total distance of 16.98mm).

- Option 2 (Concave Finish): Sealant bead should extend up the wall and along the floor for a minimum of 7.64mm each (total distance of 15.28mm).

Note: A concave bond breaking sealant bead provides a larger bond breaking surface than a mitre one when applied at the same distances, resulting in a smaller but equally effective bond breaking bead.

AS 4654.2 Fillet Requirements:

- Fillet Usage: Fillets are necessary when a membrane changes from a horizontal to a vertical plane or from one vertical plane to another.

-

Fillet Size: The standard requires a 40mm x 40mm fillet for sheet membranes and a 15mm x 15mm fillet for liquid membranes. The 15mm x 15mm requirement for liquid membranes means the hypotenuse side of the triangle (the fillet) is approximately 21.21mm.

Remember, always check the fillet/ bond breaker dimensions with the product manufacturer's Technical Data Sheet to ensure compatibility with the membrane system and alignment with the Australian standards.